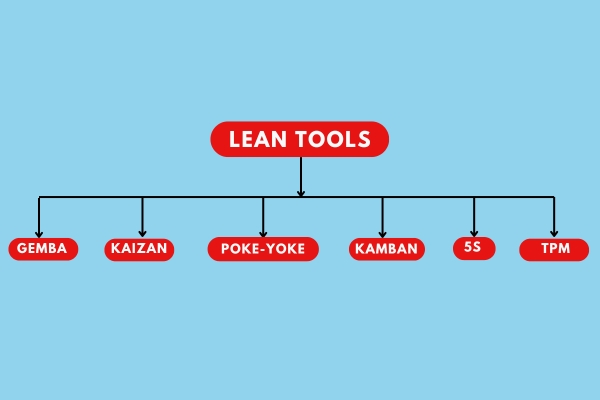

Lean Tools:

1. 5S Consultation & Implementation Services

5S consulting for industries focuses on implementing a structured workplace organization system to improve efficiency, safety, and productivity. We are one of the best 6S consultants in Coimbatore, Tamilnadu, which is based on the principles of Sort, Set in Order, Shine, Standardize, Sustain, and Safety. 6S helps create clean, organized, and efficient work environments. Jash Consultants guides companies through assessing current practices, training teams, and establishing standards to ensure lasting improvements. This approach reduces waste, enhances employee morale, and supports continuous improvement. With expert support, industries can transform their operations and build a culture of discipline and excellence.

We provide 5S Training, Implementation, & audit training in Coimbatore, Tamilnadu to identify gaps, track progress, and reinforce discipline across all departments

Benefits:

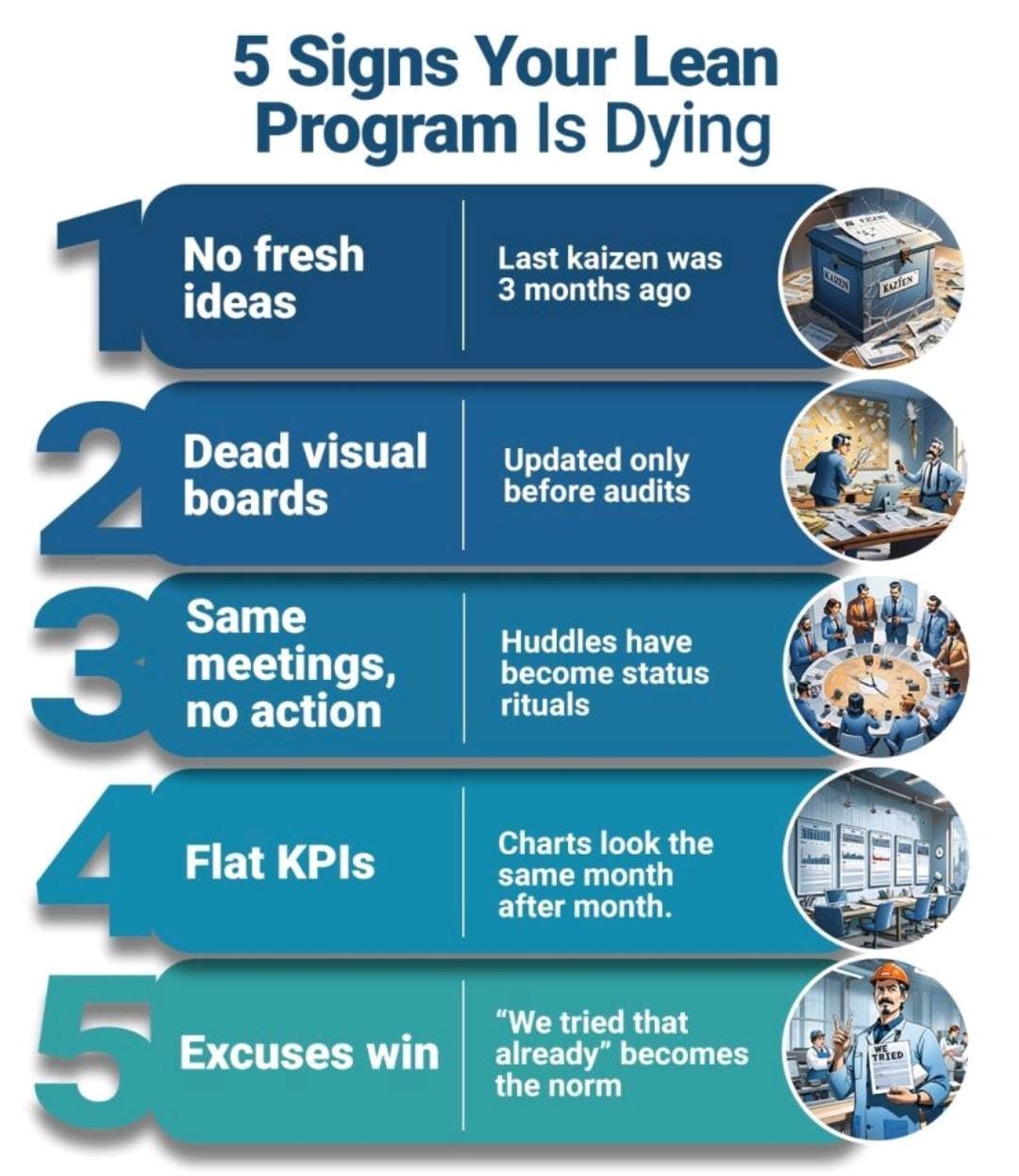

2. Kaizen and Lean Consulting

Kaizen and Lean Consulting together create a culture of continuous improvement, teamwork, and operational excellence. They help reduce waste, improve quality, boost employee engagement, increase productivity, and enhance customer satisfaction. By making small, consistent changes, organizations achieve sustainable growth and long-term success.

Benefits:

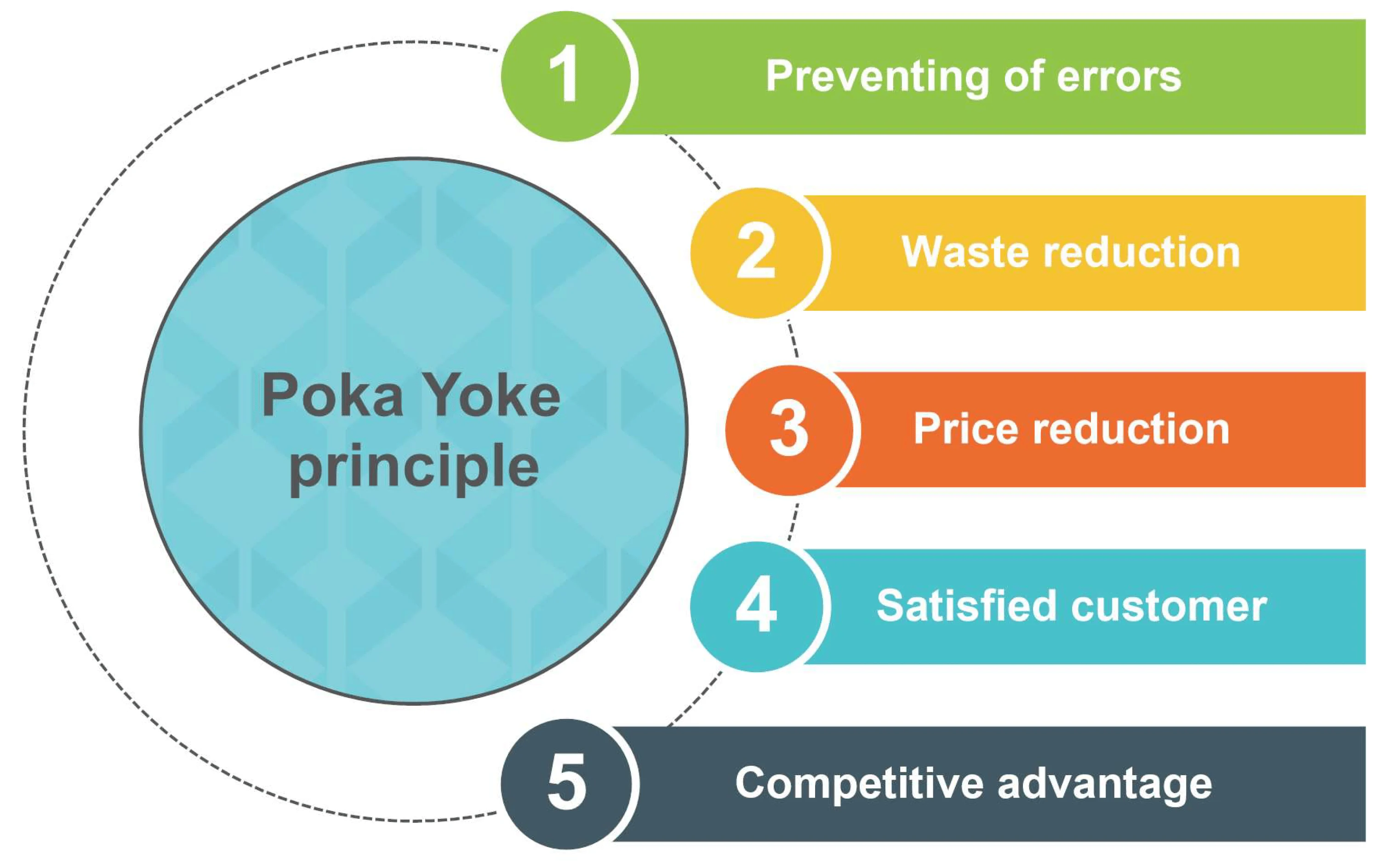

3. Poka-Yoke in Manufacturing

Poka-yoke is a mistake-proofing technique used to prevent errors before they occur. It ensures that processes are designed in a way that makes mistakes either impossible or immediately detectable. By using simple, smart solutions, poka-yoke improves quality, safety, and reliability in operations.

Benefits:

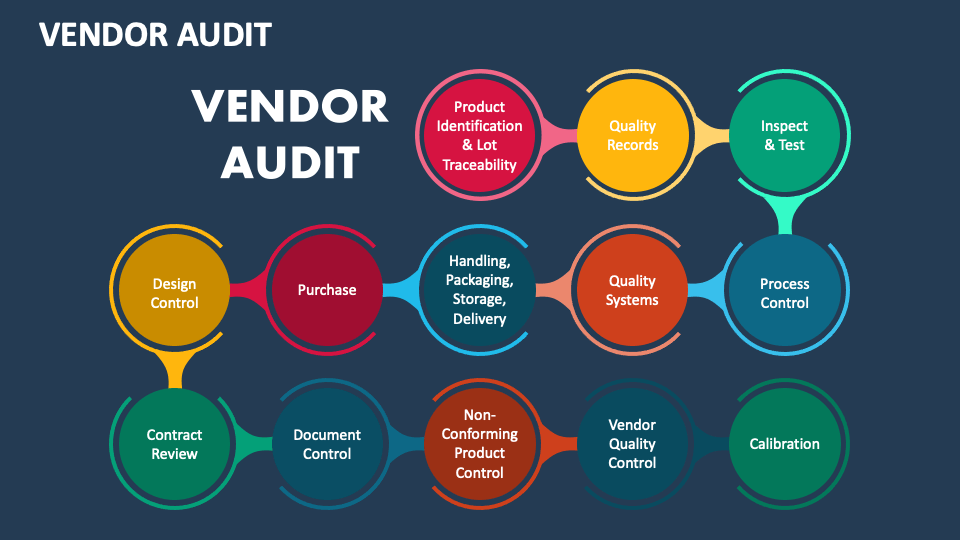

4. Vendor Audit and its Types:

A vendor audit is a process where a company evaluates and verifies a supplier’s quality systems, processes, and compliance with standards before or during the business relationship. It ensures that the vendor can consistently meet the company's requirements for quality, delivery, and service.

Types of Vendor Audits:

Benefits:

5. Just in Time Manufacturing process

Just in Time (JIT) manufacturing is a production method where materials and products are made or delivered only as needed, minimizing inventory and reducing waste. The process focuses on producing the right quantity at the right time, ensuring smooth flow and fast response to customer demands. JIT relies heavily on strong supplier relationships, efficient workflows, and precise scheduling to achieve high efficiency and lower costs.

Benefits:

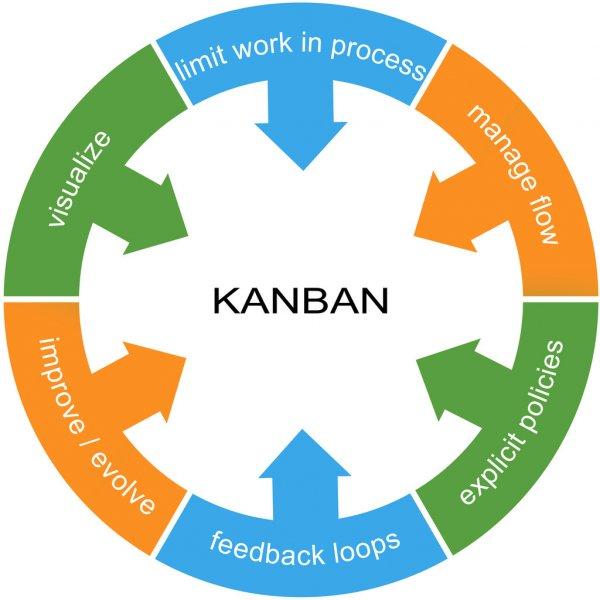

6. Kanban in Manufacturing

Kanban is a visual management method used in lean manufacturing and project management to improve workflow, limit work-in-progress (WIP), and ensure smooth production flow. It uses cards or signals to trigger the movement of materials or tasks, ensuring that inventory and work are replenished or completed only when needed.

Benefits:

7. New Product Development (NPD) & Handovering System

New Product Development (NPD) is the process of bringing a new product from idea to market. It involves stages like idea generation, design, prototyping, testing, and commercial production. The goal is to meet customer needs, stay competitive, and ensure product success in the market.

Handover in Lean means smoothly passing work or information from one person or team to another. It helps avoid mistakes, delays, and confusion. The goal is clear communication so work continues without stopping.

Benefits:

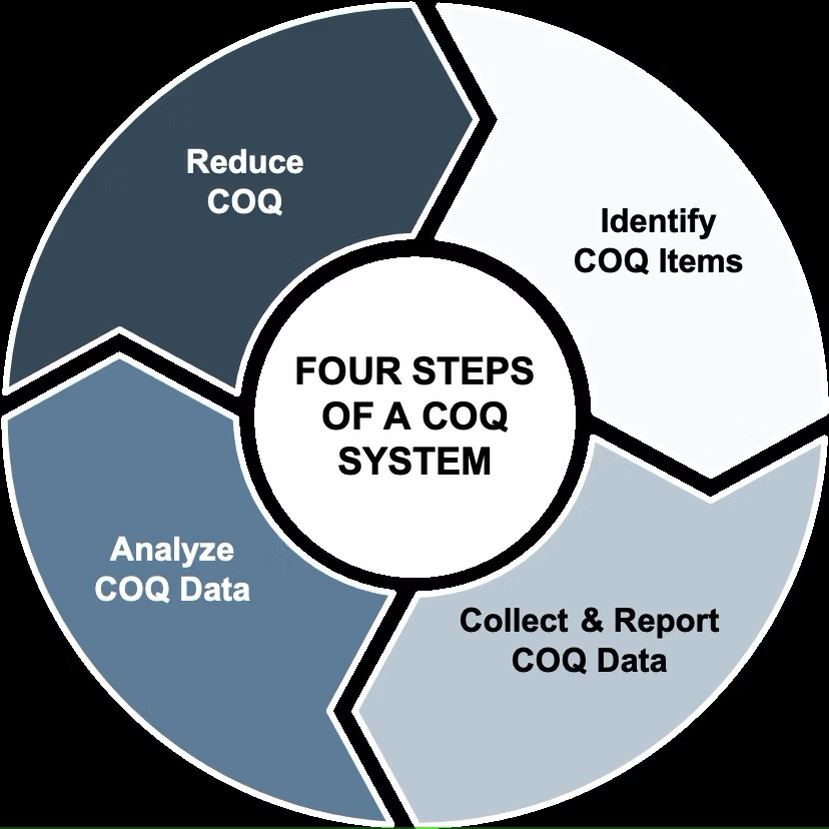

9. What is Cost of Quality in Manufacturing?

Cost of Quality (CoQ) in manufacturing refers to the total cost incurred to ensure that products meet quality standards, including prevention, appraisal, internal failure, and external failure costs. It highlights the financial impact of poor quality and the investment in quality control to avoid defects and rework. CoQ helps organizations identify areas to reduce waste and improve efficiency while delivering high-quality products.

Benefits:

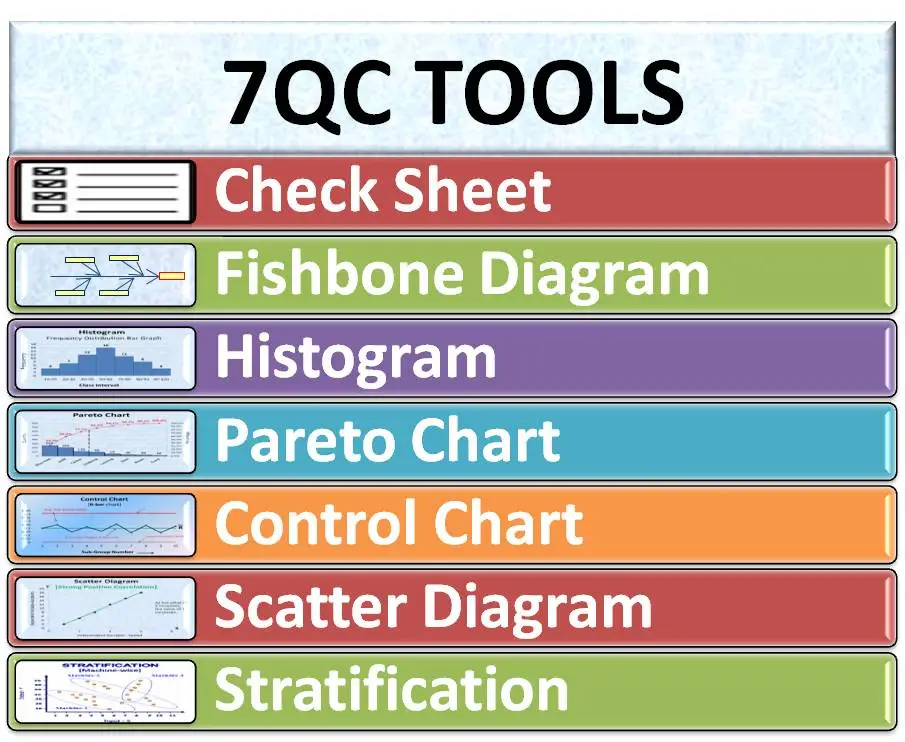

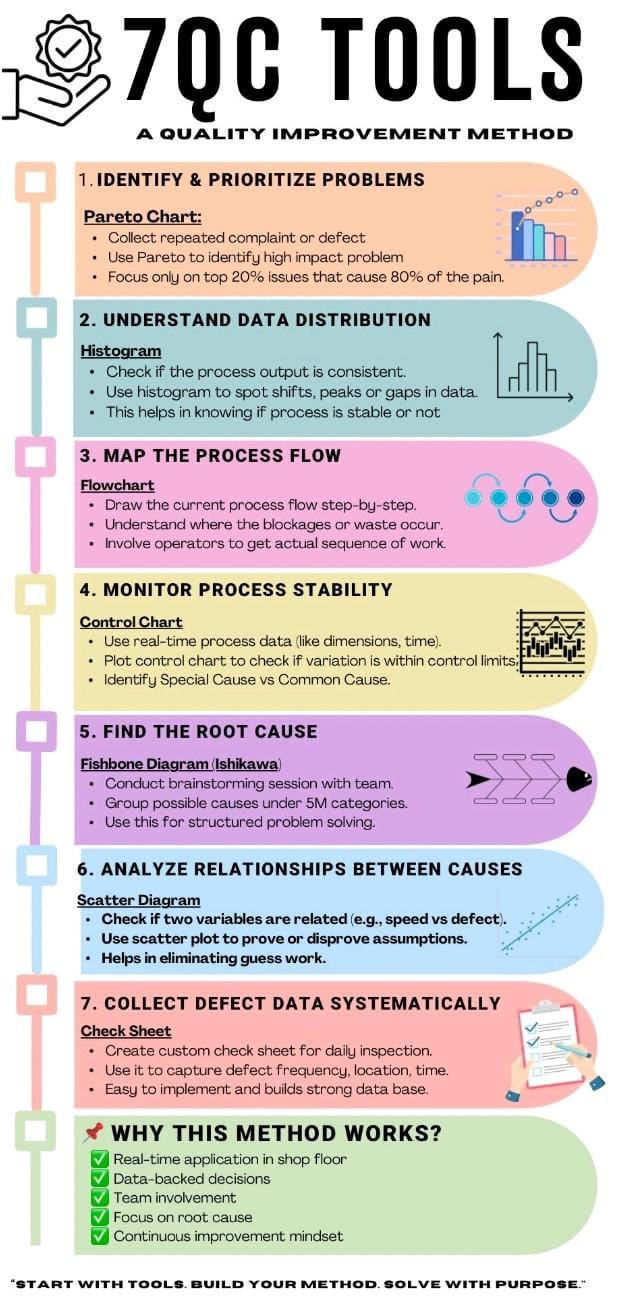

10. Problem Solving Techniques - 7 Quality Control (QC)

The 7 Quality Control (QC) tools are essential techniques for solving problems systematically in manufacturing and business processes. They include the Pareto Chart, Cause and Effect Diagram (Fishbone/Ishikawa Diagram), Control Chart, Histogram, Check Sheet, Scatter Diagram, and Flow Chart. Each tool helps visualize, analyze, and understand data to identify root causes, prioritize actions, and monitor improvements effectively. Using these tools together supports better decision-making, continuous improvement, and higher product or service quality.

Benefits

11. Risk Management and Assessment

Total Quality Leadership (TQL) tools focus on driving continuous improvement and problem-solving within an organization. They emphasize leadership involvement, data-driven decision-making, and team collaboration to address issues at all levels.

1. QMS (Quality Management System)

Risk Management: In a QMS, risk management focuses on identifying risks that could affect product or service quality, customer satisfaction, and compliance with standards (e.g., ISO 9001). Risk Assessment: It involves evaluating risks such as defects, non-compliance, delays, and resource shortages, and implementing controls to minimize their impact on product quality and organizational performance.

2. EMS (Environmental Management System)

Risk Management: EMS risk management centers around environmental impacts, such as pollution, waste, and resource depletion, to comply with environmental regulations (e.g., ISO 14001). Risk Assessment: The process assesses environmental risks like chemical spills, emissions, and waste management issues, focusing on preventive measures, sustainable practices, and regulatory compliance.

3. OHSMS (Occupational Health and Safety Management System)

Risk Management: OHSMS aims to manage risks related to workplace safety, employee health, and well-being. This includes ensuring compliance with safety regulations (e.g., ISO 45001). Risk Assessment: Risk assessments in OHSMS focus on identifying potential hazards in the workplace (e.g., machinery, chemicals, physical safety), evaluating their likelihood and impact, and putting mitigation plans in place to protect employees' health and safety.

Benefits of Risk Management and Assessment for QMS, EMS, and OHSMS:

Other Services:

Contact

Have questions or ready to get started? Reach out to us today—we’re here to help you every step of the way!

Head Office

Sai imperia Grand, Mettupalayam Road, Saibaba Colony, Coimbatore - 641 011

Branch Office

LMW Road, Periyanaickenpalayam, Coimbatore - 641020

Call Us

+91 86108 77113

Email Us

admin@jashindia.in