Best Shop Floor Management System in Coimbatore, Tamilnadu

Shop Floor Management System in Coimbatore, Tamilnadu

6 dimensions of TQM Implementation - PQCDSM

1. Productivity (P):

It reflects the efficient utilization of resources to maximize output with minimal waste. It focuses on improving equipment effectiveness, reducing downtime, and streamlining production processes through proactive maintenance, operator involvement, and continuous improvement initiatives.

2. Quality (Q):

It emphasizes building quality into the process rather than relying solely on inspection. It involves identifying root causes of defects, implementing quality maintenance techniques, and empowering operators to prevent errors at the source. Through continuous improvement and standardized procedures, TPM ensures consistent, defect-free production that meets customer expectations

3. Costs (C):

It focuses on reducing production and maintenance expenses by eliminating losses and inefficiencies. By minimizing breakdowns, rework, and waste, TPM helps lower operating costs while maintaining product quality and reliability. Strategic investments in preventive maintenance and employee training yield long-term savings and improved cost control

4. Delivery (D):

It prioritizes creating a hazard-free work environment through proactive measures and employee involvement. It integrates safety into daily operations by identifying risks, implementing preventive actions, and promoting a safety-first culture. This approach not only protects workers but also enhances productivity by reducing accidents and downtime.

5. Safety (S):

It reflects the efficient utilization of resources to maximize output with minimal waste. It focuses on improving equipment effectiveness, reducing downtime, and streamlining production processes through proactive maintenance, operator involvement, and continuous improvement initiatives.

6. Morale (M):

It focuses on boosting employee engagement, ownership, and motivation through involvement in maintenance and improvement activities. When workers are empowered and trained, they feel valued and contribute actively to operational excellence. High morale leads to better teamwork, reduced absenteeism, and a more positive, productive work environment.

Continuous Improvement

Continuous improvement in industries refers to the ongoing effort to enhance products, processes, and services through incremental and breakthrough improvements. It involves engaging employees at all levels to identify inefficiencies, reduce waste, and implement better practices. We, Jash Consulting and Training Services in Coimbatore, Tamilnadu provide constant enhancement that drives higher quality, productivity, and competitiveness over time.

- Improving product quality

- Eliminating waste

- Lowering operating costs

- Creating more value for the customer

- Maintaining a safe workplace

- Improving training and onboarding

- Increasing production efficiency

- Building a culture of continuous improvement

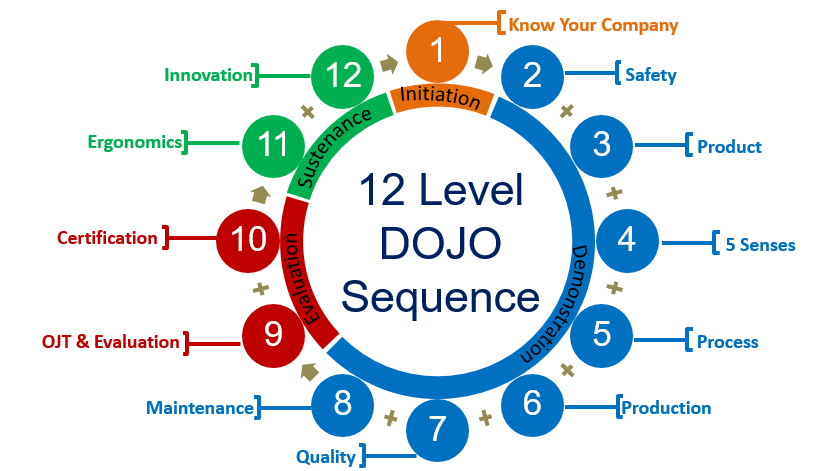

DOJO Training for Manufacturing Industries

DOJO training in manufacturing industries is a structured, hands-on learning approach designed to build employee skills, awareness, and discipline right from the shop floor. It provides a controlled environment where workers can practice standard operating procedures, safety protocols, and quality techniques before entering actual production. The training focuses on visual learning, error-proofing, and muscle memory to ensure consistency and accuracy in daily tasks

- Enhance Safety through Awareness

- Productivity and Cycle Time Improvement

- Quality Improvement and Defect Reduction

- Manpower Cost Optimization

Contact

Have questions or ready to get started? Reach out to us today—we’re here to help you every step of the way!

Head Office

Sai imperia Grand, Mettupalayam Road, Saibaba Colony, Coimbatore - 641 011

Branch Office

LMW Road, Periyanaickenpalayam, Coimbatore - 641020

Call Us

+91 86108 77113

Email Us

admin@jashindia.in